Turbocharger Knowledge

Turbocharger Knowledge

Turbocharger Benefits

The turbocharger is applied to make an engine more efficient, and makes it possible to “downsize” the engine to a smaller size without any loss in performance. This is why many 6-cylinder engines have become 4-cylinder engines and so forth. A smaller engine is cleaner so the application of turbochargers leads to reduced emissions. Nowadays it is almost impossible in the well-developed automotive industry to meet the emission standards without using a turbocharger. A turbocharger utilizes the large amount of energy remaining in the engine exhaust gas, by using this energy to drive the turbine wheel. On the other end of the turbine shaft a compressor wheel is mounted. The rotating compressor wheel sucks in fresh air through the air filter and then blows compressed air to the engine cylinders, first cooled by the intercooler. The extra oxygen contributes to an optimized combustion inside the engine significantly improving both fuel economy and emissions.

Waste Gate

A waste gate works as a control mechanism in a turbocharger. It is used to control the amount of boost provided to the engine by directing excessive exhaust gas directly into the exhaust. The waste gate can open and close by pneumatic actuators (positive and negative pressure type) or electric actuators. The wastegate will remain shut until the pressure in the compressor exceeds a certain amount, and then when that occurs, the waste gate opens and allows hot engine exhaust gas bypassing the turbine and as such not utilized for power generation and to match with the engine's request, hence the name “waste” gate.

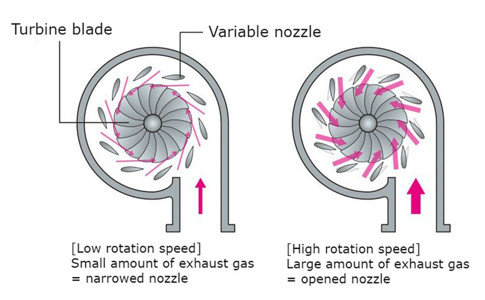

VNT-What Does It Do?

The turbochargers that using a Variable Geometry Turbine (VGT) or Variable Nozzle Turbine (VNT), are very effective in minimizing the effects of turbo lag, resulting in a more responsive throttle especially at low engine speed and much improved torque. These systems work by changing the speed and direction of the exhaust gases onto the turbine wheel. The most common VNT mechanism incorporates a ring of small movable vanes around the turbine wheel. At low engine speed, the vanes are in the “closed” position narrowing the gap between them which accelerates the exhaust gas onto the turbine wheel. At high engine speed the vanes open up slowing the exhaust gases, which prevents the turbocharger over-boosting. In most cases this level of control negates the need for a conventional wastegate.

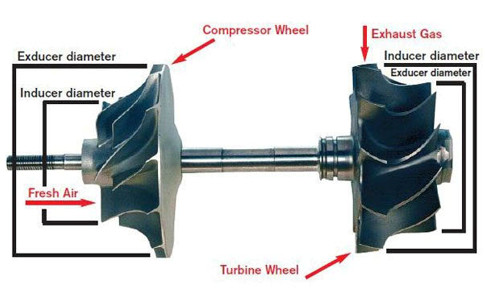

What is TRIM?

The trim of a wheel is a ratio used to describe both the turbine wheel and compressor wheel of the turbocharger. Trim is used in reference to the basic flow potential of a given wheel’s machining dimensions. Every wheel, both compressor wheel and turbine wheel, may have several trim configurations within that wheel casting. It is the trim that determines the wheel’s flow range and pressure characteristics of the turbocharger.

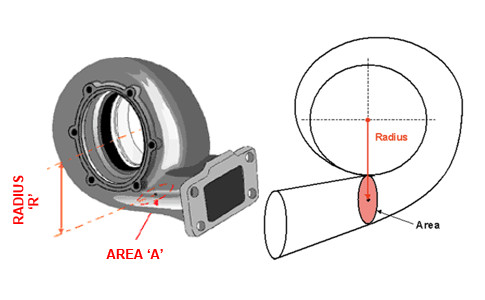

A/R Ratio

The A/R ratio of the turbo is the area of the volute at a specified location (for example at the tongue) where R is the distance from the turbine axis toward the center of A. The A/R is used during turbine matching. This is because changing the A/R changes the direction of the inflow at the rotor inlet. When increasing A/R the flow will becomes increasingly radial, while decreasing A/R the inflow will be more in the axial direction, which has an effect on the efficiency and flow capacity of the turbine.

Turbo Containment Test

The turbochager containment test's target is to assess the containment safety of turbo housings. If a compressor wheel or turbine wheel bursts, the remaining parts of the wheel must not penetrate the compressor housing or turbine housing. To achieve this, the shaft and turbine wheel assembly is accelerated to such a high speed(e.g. 1.1 times of the rated speed for compressor wheel, and with equivalent compressor wheel, for turbine wheel 1.4 times) that the respective wheel bursts. (if not burst, can manually make groove or hole on the wheel to make it easy burst). This project is an important part of the turbocharger development process, important for the reliability and safety of the turbocharger.

Turbo Failure Mode -Foreign Object Damage

Don't be the guy who uses every engine bay surface as a tool holder when working on your vehicle, doing so will eventually leaving something in the engine bay, followed by expensive repairs. Loose hardware left in the exhaust manifold or air filter or other foreign objects will result in turbocharger damage. > Compressor end: Objects such as shop towels, nuts and bolts may enter the air intake and cause damage to the compressor wheel blades. > Turbine end: Valves, valve seats, piston rings or broken manifold pieces can damage the inducer blades. The damage cannot always be recognized if the turbine wheel is still able to rotate. Often, the turbine housing must be removed to see the damage. In severe cases, the turbo shaft will bend or break.